how does a beam torque wrench work

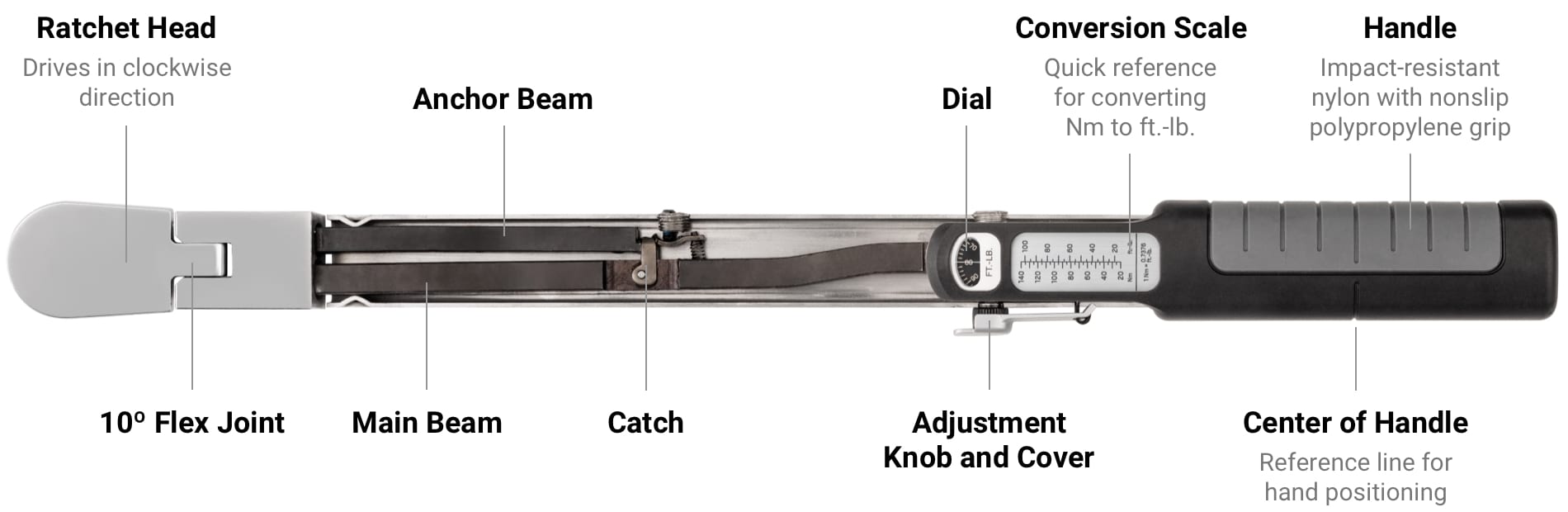

There are two beams on the beam torque wrench. These tools are easy to use and read the torque value.

Presa 3 8 In Drive 0 Ft Lbs To 80 Ft Lbs Beam Style Torque Wrench Ps00600

It helps extend the accuracy of the tool longer that is safe even on maximum loading.

. Ad Looking for the Best Torque Wrenches. Beam style torque wrenches contain a floating handle with allows the handle to pivot as you turn the wrench. We look at Beam split beam digital and click style torque wrenchesBecome a Supporterwwwpatreo.

Thus the end of the indicating beam points to the magnitude of the torque that is currently being applied. Beam and click torque wrench does the same work. Split beam wrenches are more accurate practical durable and easy to operate.

One works as the handle and deflects when a user turns it while the second beam gives the reading. Theres nothing to set on it you just tighten the bolt and as you do you watch the. Only aligning the zero mark is required when calibrating a beam torque wrench.

There are two main types of torque wrenches clicker and beam. A torque wrench is a valuable and necessary tool for many mechanics including those who work on motorcycles. The deflecting beam torque wrench applies the principle of adding torque to a deflecting beam rather than a coil spring.

A torque wrench is a useful piece of equipment calibrated and used for a stated amount of load or pressure to a bolt or nut. They are simple durable and affordable. And the other part gives out the reading.

When held properly the handle exerts pressure on the extreme end of the tool thereby allowing precise torque application. Whether you are a workshop owner or a DIYer torque wrenches are used for a wide variety of applications from. With a Clicker you have to twist the handle quite a lot depending on the torque setting you want to preset.

When held properly the handle exerts pressure on the extreme end of the tool thereby allowing precise torque application. The wrench works by the beam being in line with zero on the scale. This is because torque is the force multiplied by the length of the tool.

How does a beam type torque wrench work. Clicker wrenches have a circular dial that clicks when you reach your desired torque value and stops turning once you reach the desired setting. Turn the handle of it and tighten the adjustable dial.

Take the wrench and loosen the adjustable dial. The torque amount applied relies on the amount of force you put on the handle and the torque wrenchs whole length. One steel beam deflects when you pull the handle and the other pointer beam remains intact while applying force.

The pointer beam at the end will show the readings at the digital scale that has a series of numbers. 2 Million Customers Choose Zoro. The tool has two beams.

Beam torque wrenches consist of two beams one steel beam deflects expectedly when you pull the handlebar and the other beam pointer gives a reading after the pulling is completed. The torque wrench may display the torque being applied in foot-pounds ft. Among several torque wrenches the beam type torque wrenches are one of the most popular.

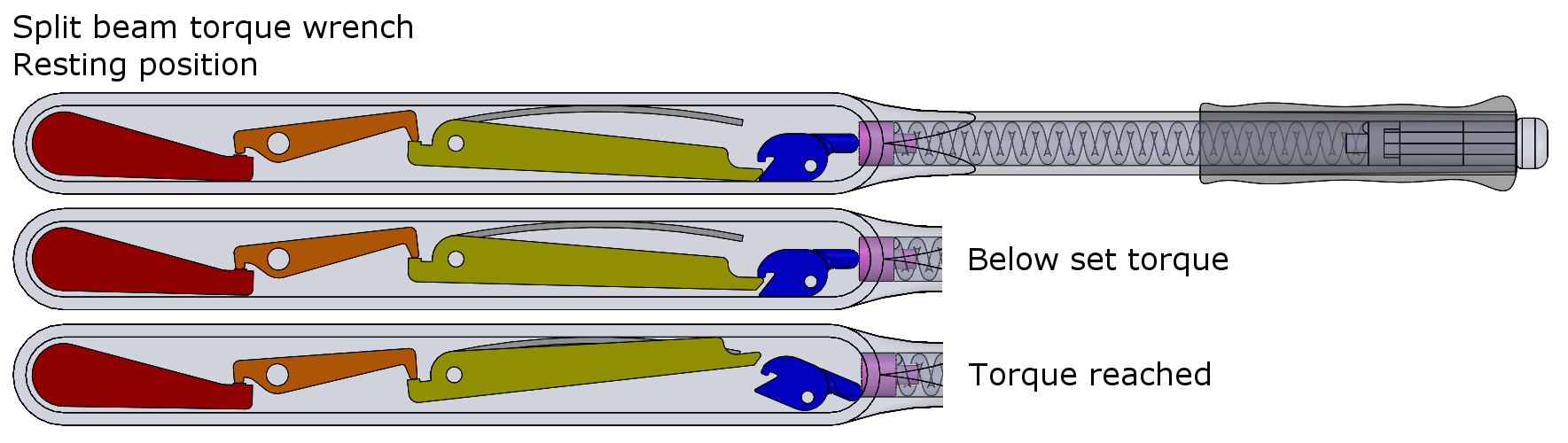

The torque amount that needs to be applied is dependent on the amount of force that you are applying on the handle and the overall length of the torque wrench. How Different Torque Wrenches Work. A Split Beam Torque Wrench belongs to the family of beam torque wrenches but operates like a Click Wrench but better.

It works with two beams. A split beam torque wrench is a subcategory of beam wrench. One of the simplest torque wrench is would be a beam style torque wrench.

Value is always important but the range for beam style torque wrench is relatively. We try to answer the question how do torque wrenches work. A torque wrench is a tool that is calibrated and is used for a specified amount of pressure or load to a nut or bolt.

A split beam torque wrench is a simple durable précised tool that is affordable. First tighten the bolts with the wrench. Compare Before You Buy.

You can push the handle to get the desired readings. Ad Free 2-day Shipping On Millions of Items. These are usually heavy-duty tools and can range from 100 to 800 dollars.

Now hold on to the handle and place the fasteners tip on the left side with the handle. The torque wrench allows the mechanic to precisely tighten bolts and nuts to the correct level of tension ensuring that the parts are secure and will not come loose over time. One acts as a handle that deflects predictably when one turns it.

How does a beam torque wrench work. This is achieved by moving the beam so that it lines up 3. Comfort Comfort is the other primary factor we took into consideration when evaluating beam style torque wrench.

This type of wrench is simple inherently accurate and inexpensive. When the wrench is used to apply torque the lever bends and the indicating beam stays straight. The wrenches are a subcategory of torque wrench and a type of beam torque wrench.

Beam style torque wrenches contain a floating handle with allows the handle to pivot as you turn the wrench. The beam torque wrench is the oldest type of torque wrench on the market and its also one of the easiest to use. This value of torque is displayed on the associated meter or dial.

Then adjust this as you need. Ad Find Deals on precision instruments split beam torque wrench in Hand Tools on Amazon. Beam wrenches have a rigid bar set between two fixed posts.

One of the torque wrench beams is considered a handle that predictably deflects when you turn it. You turn the handle to set the pressure as indicated on the. After all the more comfortable a beam style torque wrench is the less likely you will dislike it.

Find and Compare the Best Torque Wrenches Based on Price Features Ratings Reviews. It uses a simple lever system that allows you to measure how much force you are applying as you turn a nut or bolt with an attached handle. Then until you hear a click turn the handle clockwise.

How Complete GuideTorque wrench calibration is an important topic to discuss because torque wrenches are an essential tool for anyone involved in mechanical work dealing with bolts and screws. A torque wrench uses a deflection beam or a calibrated spring system to find the amount of torque being applied to a nut or a bolt. Beam torque wrenches are accurate to within 1-3 with the middle third of the range being closer to 1.

Anyways split beams have two beams. The split-beam torque wrenches let the users apply the required torque making them more accurate in their work. Torque Wrench Calibration Why When.

The tool provides accurate reading and produces a clicking sound if it reached the tightness required. This is because torque is the force multiplied by the length of. Split Beam Torque Wrench.

The best split beam torque wrenches are accurate to up to 2. Lbs or Newton-meters Nm. We pay attention to softness shape and size.

1 2 Flexible Split Beam Torque Wrench

File Split Beam Clicker Torque Concept Png Wikimedia Commons

3 8 1 2 Inch Drive Split Beam Torque Wrench Set 2 Piece Trq99902 Tekton

How To Use A Beam Style Torque Wrench Wrench Guide

Tw 1 2 Beam Type Torque Wrench 0 14 Nm Park Tool

Split Beam Torque Wrench How It Works

Tw 2 2 Beam Type Torque Wrench 0 60 Nm Park Tool

Split Beam Torque Wrench How It Works

How To Apply A Torque Wrench Youtube

Split Beam Torque Wrench 1 2 Drive 50 250 Ft Lb Torque Range 4 Olsa Tools Canada

Certified 1 2 In Drive Beam Type Torque Wrench Canadian Tire

Split Beam Torque Wrench How It Works

How Does A Split Beam Torque Wrench Work Wrench Guide

How To Use A Torque Wrench Diy Family Handyman

Olsa Tools Split Beam Torque Wrench Youtube

Best Practices For Torque Wrench Repair

Deflecting Beam Torque Wrench Review Comparison Youtube

Neiko 03727a 1 4 Drive Beam Torque Wrench 0 80 Inch Pounds 0 9 Newton Meter Precision Beam Style Torque Wrench For Bicycle And Automotive Amazon Ca Tools Home Improvement